Home » Silt and Sediment Control » Chatoyer Silt Curtain

Chatoyer has manufactured over 500,000m of Silt Curtain since 2009. These floating turbidity curtains have been deployed in various projects around Australia, New Zealand and in Papua New Guinea, New Caledonia, Fiji and Vanuatu.

See the range of applications in the video below.

Our team has extensive experience designing curtains for applications you might not even know a Silt Curtain could be used for!

We’ve fabricated floating turbidity curtains for extreme environments like the open ocean, tropical tidal ranges, high-velocity winds and fast-flowing rivers. We’ve used special materials for acidic tailings dams. We’ve made curtains 20m deep. We’ll advise on anchoring. We are very familiar with the waterways around Australia. Our use of high-quality materials, attention to detail and workmanship excellence has resulted in Chatoyer leading the market in quality Silt Curtain fabrication. Chatoyer’s floating turbidity curtains have a reputation for reliable performance and durable construction.

Silt Curtains are generally required by marine service companies, construction companies, erosion and sediment control contractors, consultants, councils and state road authorities for the following types of projects:

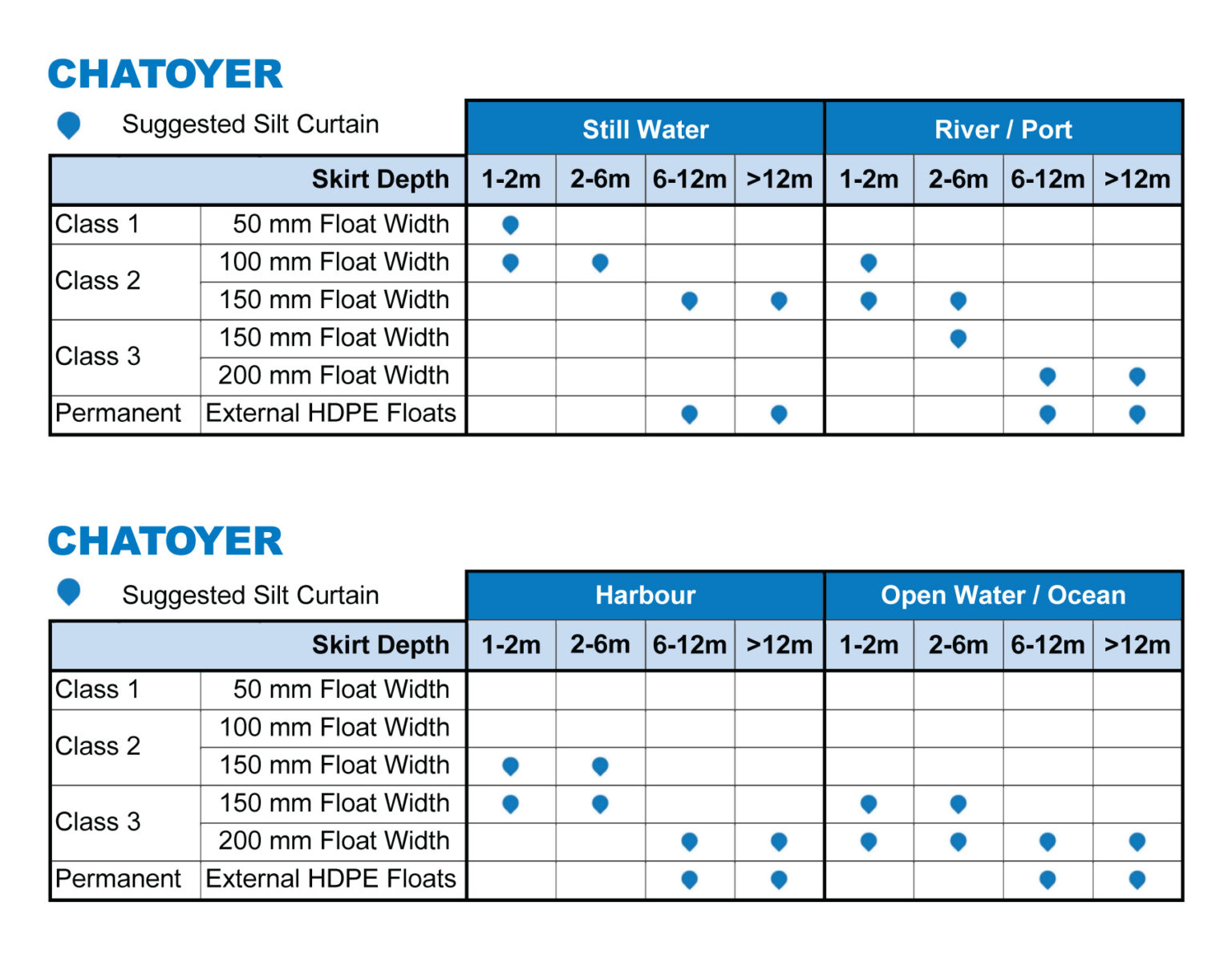

Our popular designs are categorised into types we refer to as a Class. Each Class design is based on functionality that generally suits common applications and operating sea states. The range of turbidity curtains is made in 20m lengths. Multiple lengths are connected to cover the overall required span. Floating silt booms can be customised to suit specific project requirements such as project longevity, operating sea states and government regulations, to name a few. We specialise in custom and Class 3 heavy-duty Silt Curtains made to spec for harsh conditions, long-term deployment, extra deep skirts and special functionality for vessel traffic, shoreline approaches, tides and anchoring. For permanent or heavy-duty turbidity curtains, we offer a range of materials, floats, accessories and technical advice.

Chatoyer developed this simple categorisation to assist our clients in selecting an appropriate silt boom design. Below is a guide we use in consultation with clients illustrating our suggested options per waterway and the fundamentals of each design class.

Low-Risk Applications

Little to no tidal, wave and/or wind forces.

Example: lagoon, pond, stream

Medium-Risk Applications

Moderate wind and/or water forces.

Example: river, calm harbour

High-Risk Applications

Strong wind and water forces.

Example: open ocean, harbour, river mouth

Chatoyer supplies silt curtains with the skirt furled and multiple sections connected up to a length of 100 metres per pallet. This enables immediate deployment on site.

When projects require a large length of curtain resulting in numerous pallets, each pallet will be clearly identified and numbered. Pallet sections will be joined in consecutive fashion and pallets should be laid down as near as possible to the deployment zone.

Since the purpose of a floating silt fence is to disrupt the water flow and allow the suspended sediment to settle, your curtain should be deep enough to facilitate the following:

Allow a minimum half metre gap between the curtain and the sea bed at low tide. Silt curtains are intended to promote the settling of sediment by driving particles closer to the sea bed. Water will always find the path of least resistance, therefore the water will pass between the lower edge of the curtain and the sea bed. Sediment must be forced deep enough to improve settlement. The gap between the curtain and sea bed provides a significantly more effective pressure release than the porosity of geotextile.

The deeper the curtain, the greater the hydraulic loading which can cause the curtain to flare, resulting in additional horizontal loads. Further, if the curtain penetration is too great, the water that passes beneath the skirt will be squeezed through a small gap resulting in possible further erosion of the sea bed and a resuspension of particulate into the upper water column further downstream.

Silt curtain effectiveness is considered as the degree of turbidity reduction achieved within the controlled area relative to the turbidity levels outside of the area. Factors which affect this effectiveness are:

The silt curtain is not designed to dam the turbid water. Instead, it provides a control for the dispersion of the sediment laden water and allows this suspended silt to settle. It is widely accepted that the interaction between the water column and curtain is a crucial factor in determining the efficiency of the silt curtain. It is integral to the design that the hydrodynamic loads are understood. These loads are the forces applied to the moorings and silt curtain resulting from currents, winds and waves. These forces can affect the buoyancy and ballast ratio, optimal skirt depth and choice of moorings and anchors.

One of the critical reasons for a silt curtain failure is that the installation was not completed correctly or with enough diligence. This can then be further impacted by a lack of maintenance program. We strongly recommend that a professional service is employed to install your system. A failure of the Silt Screen can be avoided if care is taken at the front end.

To assist with installation, ensure a large enough area is available to work with the silt curtain prior to deployment. Access to the waterways should be understood and coordinated in advance of the installation. The anchoring system needs to be installed in the waterway prior to deploying the curtain. Once the desired length of silt curtain is connected, the furled curtains can be towed to the desired deployment location at a maximum speed of two to three knots. Ensure the curtain remains furled and is secured to the anchoring system. After the furled curtain has been anchored, the boom should be checked to confirm the skirt is not twisted around the flotation chamber. Once the furled and untwisted curtain is anchored in the right location, remove the ties furling the curtain and allow the system to drop into place.

To recover the silt curtain, disconnect the silt curtain from the anchoring points and furl the curtain skirt. Then remove the mooring systems. Tow the system back to the launching site for removal from the waterway and responsible disposal.

Silt curtains can be cleaned and properly stored for reuse. If the curtain has been inspected, is in good condition and deemed suitable for reuse, it can be cleaned down with a high-pressure washer to remove biofouling, silt and sediment from the geotextile.

Once thoroughly dry, the curtain can be repacked on a pallet and stored. If serviced and stored properly, a high-quality silt curtain system can be reused numerous times.

Our team will provide free consultations and help spec curtains if required. Chatoyer offers:

Looking for product information? Want to discuss your fabrication requirements? Need a quote?