- About

- Products

- Bund Accessories

- Ultra-Self Bailer

- Chatoyer Ground Mats

- Industries

- Case Studies

- Sales

- Contact

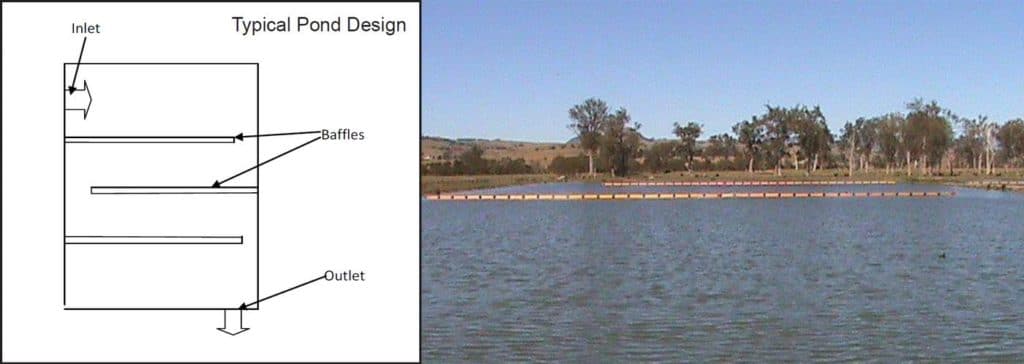

Home » Silt and Sediment Control » Floating Baffles

Chatoyer has been fabricating Floating Baffles since 2009. These baffle curtains have been installed in numerous municipal, mining and industrial scenarios around Australia.

Chatoyer Floating Baffles create systems that offer an easy, flexible and economical way to improve efficiency and effectiveness of a maturation pond, lagoon, settling basin or any other body of quiescent water. These Floating Baffle Curtains are designed and installed with the specific purpose of controlling or directing water flows such as reservoir baffles that create bio-separators.

Once installed, Floating Baffles redirect flows around the curtains. The pond baffles act like walls in the water. The water is forced to follow the path dictated by the installed baffle curtains in a snake like flow rather than flowing in a more direct path from inlet to outlet. This creates improved Hydraulic Retention Time (HRT).

Floating Baffles are an economical option that will improve the effectiveness of your pond or dam by:

Chatoyer uses only the highest quality materials and designs proven reliable from years of experience:

Chatoyer can offer advice on mooring, anchoring systems and buoys.

Suspended baffles normally extend the full depth of the pond. Profiles are specifically fabricated to follow the pond floor. Optional windows can be incorporated into the design. Working directly with your engineering and technical teams, Chatoyer Floating Baffles are constructed to your exact engineering requirements generating the optimum waterway performance within your pond system.

Each baffle curtain is customised and built to suit your lagoon or tank with project life spans of up to 20 years. Baffles are built for enclosed spaces such as concrete or steel treatment tanks. Baffle curtain designs provide the necessary detention time with the desired flow path to suit each distribution system.

Industries where our systems have been installed include oil & gas, mining, urban water utilities and industrial waste water treatment plants. Chatoyer’s expert team provides engineer design advice and technical drawings for each project.

Floating Baffle systems require routine maintenance and inspection. A program must be developed to sustain the system through it’s project life. These semi-annual or annual routine checks are supported by a detailed checklist and report.

Looking for product information? Want to discuss your fabrication requirements? Need a quote?