Home » Spill Containment on Land » Hard Tops » Ultra-IBC Hard Top

The Ultra-IBC Hard Top spill pallet is a robust containment solution designed specifically for large containers such as IBCs and tanks. Constructed entirely of polyethylene, this roll-top unit not only provides security against unauthorised access but also offers reliable protection against harsh environmental conditions like rain, sunlight and other elements.

The unit is easy to use – simply use your forklift or other equipment to place your IBC or tank inside, close the doors and you can rest assured that your valuable liquid contents are well protected from spills and leaks.

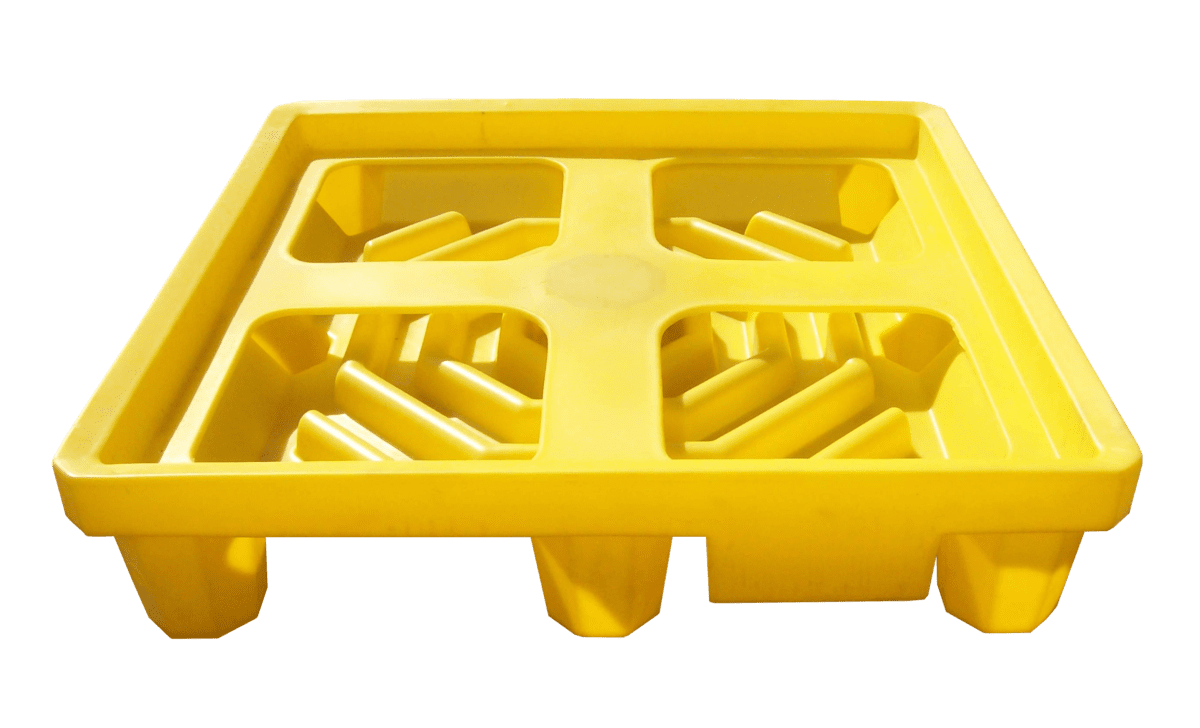

The innovative “Cross of Life” design protects the pallet’s structural integrity during heavy loads over time. As more weight is applied to the top of the pallet, the Cross of Life design draws the all-polyethylene sides towards the center instead of allowing them to sag outwards. Learn more.

The innovative “Cross of Life” design protects the pallet’s structural integrity during heavy loads over time. As more weight is applied to the top of the pallet, the Cross of Life design draws the all-polyethylene sides towards the center instead of allowing them to sag outwards. Learn more.

![]()

Benefit from the industry’s most robust warranty, offering five years of protection against any defects in material or workmanship. Learn more.

Product Code | Description | Length (mm) | Width (mm) | Height (mm) | Weight Capacity (kg) | Containment Capacity (L) | Weight (kg) |

CHU1162 | IBC Hard TOP, No Drain | 1638 | 1574 | 2438 | 3855 | 1362 | 238 |

CHU1161 | IBC Hard TOP, With Drain | 1638 | 1574 | 2438 | 3855 | 1362 | 238 |

The standard dimensions for a typical plastic IBC in Australia are as follows:

These dimensions result in an IBC capacity of 1000 litres.

Yes, there are forklift pockets on two sides of the pallet.

No, we do not recommend moving loaded hard tops.

The pallet has a 3855kg capacity. This is for uniformly distributed loads. An IBC that is supported by a pedestal post or feet focuses all of its weight on those feet. If the dimensions of those feet are not large enough to properly displace the weight on the spill pallet’s grating, it could be an issue. As a precaution, steel plates (at least 304mm x 304mm) can be used under the feet in order to more evenly distribute the weight over a greater area.

No, the spill pallet is not completely waterproof. It is more accurately described as weatherproof. In other words, in standard weather conditions, your drums and/or containers should be protected and water gathering in the pallets is not a concern. However, during very gusty conditions or very heavy rainfall, some water may get into the unit. It is good practice to inspect the interior of the hard top after any severe weather.

It is not recommended.

Because of the different conditions and circumstances that a product like this is used under, it is impossible to put a number on a question like this. However, it is worth noting that (with the exception of a few pieces of hardware) the entire unit is made with polyethylene, which will not rust or corrode. In addition, we use a UV inhibitor to prevent degrading effects from sunlight. Finally, we offer the industry’s best warranty and will cover any material or workmanship defects for up to five years.

The IBCs are NOT included. They are only used in our photographs to help convey the product’s application.

The standard drain is a threaded hole in the sidewall with a 19mm polyethylene plug with NPT threads installed.

We recommend using a pump like the bladder pump (Product CHU2345) used with our Ultra-Spill Deck Bladder Systems. Click here to see a video of it in action.

A single IBC Hard Top ships on an oversized skid (1524mm x 1625mm), freight class 250 and NMFC 156600-3.

UltraTech’s general response to this question is at least ten (10) years. You can expect longer, but the actual life is dependent on several factors. UltraTech has been making outdoor spill containment products since 1993. We have a good sense of realistic life expectancy based on all those years of experience. UltraTech uses the highest-rated UV package in the resin formulation it uses to create the longest outdoor life available for a PE product

The most important environmental factors are ultraviolet exposure and chemical exposure. In the absence of chemical compatibility concerns (determined by the UltraTech compatibility chart for PE products), the next most important factor for outdoor, polyethylene spill containment products will be ultraviolet irradiation (UV) exposure. The most important factors with reference to UV are thickness, UV Inhibitor (UVI) content, and pigment color, type, and concentration. Ultraviolet irradiation exposure causes molecular structure and bond changes that result in the embrittlement of PE. Very thin PE can become brittle and fracture in less than a year (think contractor’s PE Visqueen sheeting). Thicker parts take longer to break down. The addition of UV Inhibitors to the PE allows it to sustain more UV exposure without breaking down. Darker pigments, inorganic pigments, and higher concentrations of pigments also individually and collectively will give PE a longer life before appreciable UV damage occurs.

There is an outdoor spill containment product that has been in use in northeast Florida since 1986 and is still in active use today. UltraTech suggests its Ultra-Track Pans, used for outdoor railroad track spill containment, have a minimum of a twenty-year life.

MASTER DISTRIBUTOR OF:

Looking for product information? Want to discuss your fabrication requirements? Need a quote?